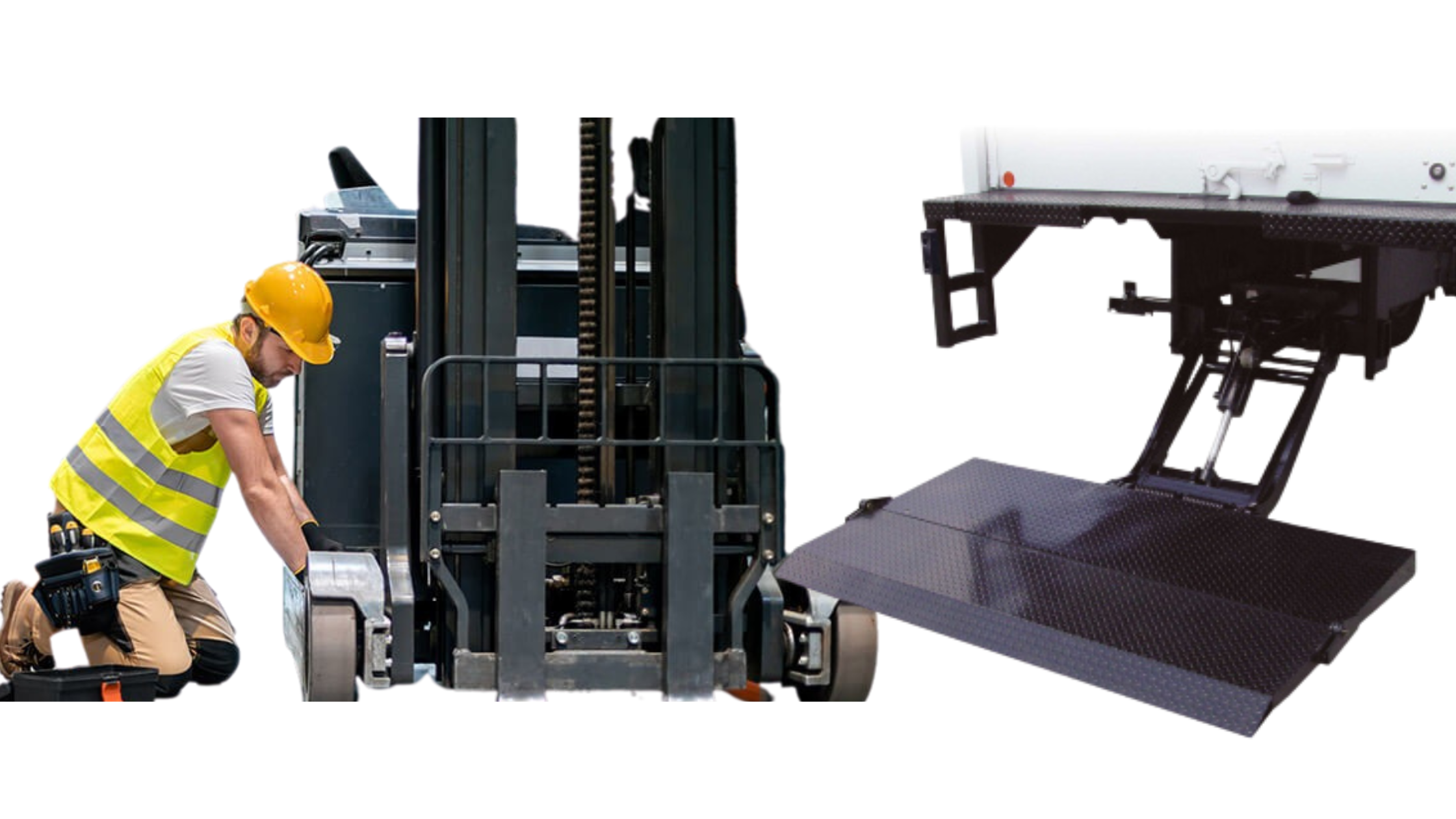

You can tell a lot about a warehouse by the small things attached to its forklifts. Steering knobs, warning lights, fork extensions—they’re not flashy, but they speak volumes about how seriously a team takes efficiency and safety. In the middle of a busy shift, it’s not the forklift itself that makes the difference. It’s how that machine is customized for the job.

Some accessories are about comfort. Others protect people or products. A few are there just to squeeze an extra 2% out of your operation every day. And if you've ever wrestled with an awkward pallet or strained to see around a tall load, you already know how big that 2% can feel.

Ready to upgrade your forklift? Explore our collection of forklift attachments today!

Why Forklift Attachments Matter

Forklift attachments are more than just add-ons—they’re game-changers for industries that rely on material handling. By enhancing the versatility, safety, and efficiency of forklifts, attachments can transform operations across various sectors. Here’s how they make a difference:

Increased Productivity

According to a study by the Material Handling Institute (MHI), forklift attachments can increase productivity by up to 30% in material handling operations. For example:

- Fork Positioners: These attachments allow operators to adjust fork spacing without leaving the cab, reducing load-handling time by 15-20%.

- Push-Pull Attachments: Used for handling slip sheets, these attachments can reduce loading and unloading times by up to 25% compared to traditional pallet handling.

- Side Shifters: By enabling operators to adjust loads horizontally without repositioning the forklift, side shifters can improve efficiency by 10-15%.

Want to see how forklift attachments can transform your operations? Contact our team for a free consultation!

Improved Safety

Safety is a top priority in material handling, and forklift attachments play a critical role. The Occupational Safety and Health Administration (OSHA) reports that 20% of forklift accidents are caused by unstable loads. Attachments like load stabilizers and fork extensions can significantly reduce this risk. For example:

- Load Stabilizers: These attachments reduce load sway, decreasing the risk of tip-overs and dropped loads by up to 40%.

- Fork Extensions: By providing better support for long or awkward loads, fork extensions can reduce accidents caused by unbalanced loads by 25%.

Safety is our top priority. Schedule a safety inspection or operator training today!

Types of Forklift Attachments

Forklift attachments come in many forms, each designed to handle specific tasks. Here’s a breakdown of the most common types and their applications:

1. Side Shifters

Side shifters allow operators to move loads left or right without repositioning the forklift. This is especially useful in tight spaces where precision is key.

- Best For: Warehouses with narrow aisles or high-density storage.

- Benefits: Reduces the need for manual adjustments and improves load placement accuracy.

2. Fork Positioners

Fork positioners enable operators to adjust the spacing between forks to accommodate different pallet sizes. This eliminates the need to manually reposition forks, saving time and effort.

- Best For: Facilities handling a variety of pallet sizes.

- Benefits: Increases efficiency and reduces operator fatigue.

3. Rotators

Rotators are designed to tilt and rotate loads, making them ideal for handling barrels, drums, or irregularly shaped items.

- Best For: Industries like construction, agriculture, and manufacturing.

- Benefits: Improves load stability and reduces the risk of accidents.

4. Fork Extensions

Fork extensions increase the length of the forks, allowing operators to handle longer or oversized loads like lumber, pipes, or double pallets.

- Best For: Construction sites, lumberyards, and warehouses with oversized loads.

- Benefits: Enhances load stability and reduces the need for multiple trips.

5. Clamps

Clamps are used to grip and handle items like barrels, boxes, or bales. They come in various types, including carton clamps, drum clamps, and bale clamps.

- Best For: Retail, agriculture, and beverage industries.

- Benefits: Reduces product damage and improves handling efficiency.

Not sure which attachment is right for you? Browse our full range of forklift attachments and find the perfect fit for your needs.

Benefits of Used Forklift Attachments

While new attachments are great, many warehouses rely on used forklift attachments to round out their equipment. They're more affordable, often refurbished, and in many cases, available with the same load ratings as new models. If you're browsing the used market, check for signs of wear at weld points and locking mechanisms. Good maintenance practices extend the life of even used forklift forks.

Used forklift attachments are gaining popularity not only because of price but because of availability. During supply chain slowdowns, it’s often faster to find quality used attachments locally than to order new ones on backorder.

Safety Considerations for Forklift Attachments

Safety is a big reason why the right attachment matters. A mismatched or damaged fork attachment can lead to tipping, dropped loads, or worse. It’s not just about efficiency—it’s also about risk mitigation. OSHA recommends regular inspections of all attachments and that operators be trained specifically on each attachment type.

Forklift fork attachments aren't universal, either. Compatibility depends on carriage size, capacity rating, and hydraulic hookup if powered. For example, fork attachments for forklifts with hydraulic tilt or rotation will require additional hoses and control levers.

Need help ensuring your attachments are safe and compatible? Contact our team for expert advice!

How to Choose the Right Forklift Attachment

Choosing the right forklift attachment depends on several factors, including the type of forklift, the work environment, and the specific tasks you need to perform. Here’s a step-by-step guide to help you make the best decision:

1. Assess Your Forklift Type

- Compatibility: Ensure the attachment is compatible with your forklift’s carriage size, weight capacity, and hydraulic system.

- Power Requirements: Some attachments, like rotators or clamps, require additional hydraulic hookups. Verify that your forklift can support these features.

2. Evaluate Your Work Environment

- Indoor vs. Outdoor Use: For indoor environments, consider attachments like side shifters or fork positioners that improve precision. For outdoor use, opt for durable attachments like rotators or fork extensions that can handle rough terrain.

- Space Constraints: If you’re working in tight spaces, choose attachments that enhance maneuverability, such as fork positioners or articulating jibs.

3. Consider Your Load Requirements

- Weight: Ensure the attachment can handle the maximum weight of your loads. Exceeding capacity can lead to equipment failure and safety hazards.

- Size and Shape: For irregularly shaped loads, consider attachments like clamps, rotators, or multi-pallet handlers.

- Frequency of Use: If you’ll be using the attachment frequently, prioritize durability and ease of use.

4. Think About Long-Term Needs

- Versatility: If your operations are likely to change, choose attachments that can adapt to different tasks. For example, multi-function clamps can handle both boxes and drums.

- Future-Proofing: Consider investing in attachments that can grow with your business, such as those with adjustable features or higher capacity ratings.

Still unsure which attachment is right for you? Contact our experts for personalized recommendations!

FAQs

Q: What’s the difference between new and used forklift attachments?

A: New attachments come with a warranty and are guaranteed to meet OEM standards, while used attachments are more affordable and often refurbished to like-new condition. Both options can deliver excellent performance when chosen carefully.

Q: How often should I inspect my forklift attachments?

A: OSHA recommends inspecting attachments before each use and conducting a thorough inspection at least once a year. Regular maintenance ensures safety and extends the lifespan of your equipment.

Q: Can I use the same attachment on different forklift models?

A: Compatibility depends on factors like carriage size, weight capacity, and hydraulic systems. Always check the manufacturer’s specifications before using an attachment on a different forklift.

Q: Are used forklift attachments safe?

A: Yes, used attachments can be safe if they’ve been properly inspected and refurbished. Look for attachments with a documented service history and no signs of excessive wear or damage.

Q: What’s the most versatile forklift attachment?

A: Fork positioners are highly versatile, as they allow operators to adjust fork spacing for different load sizes. However, the best attachment for you depends on your specific needs and work environment.

Have more questions? Contact our team for answers!

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.