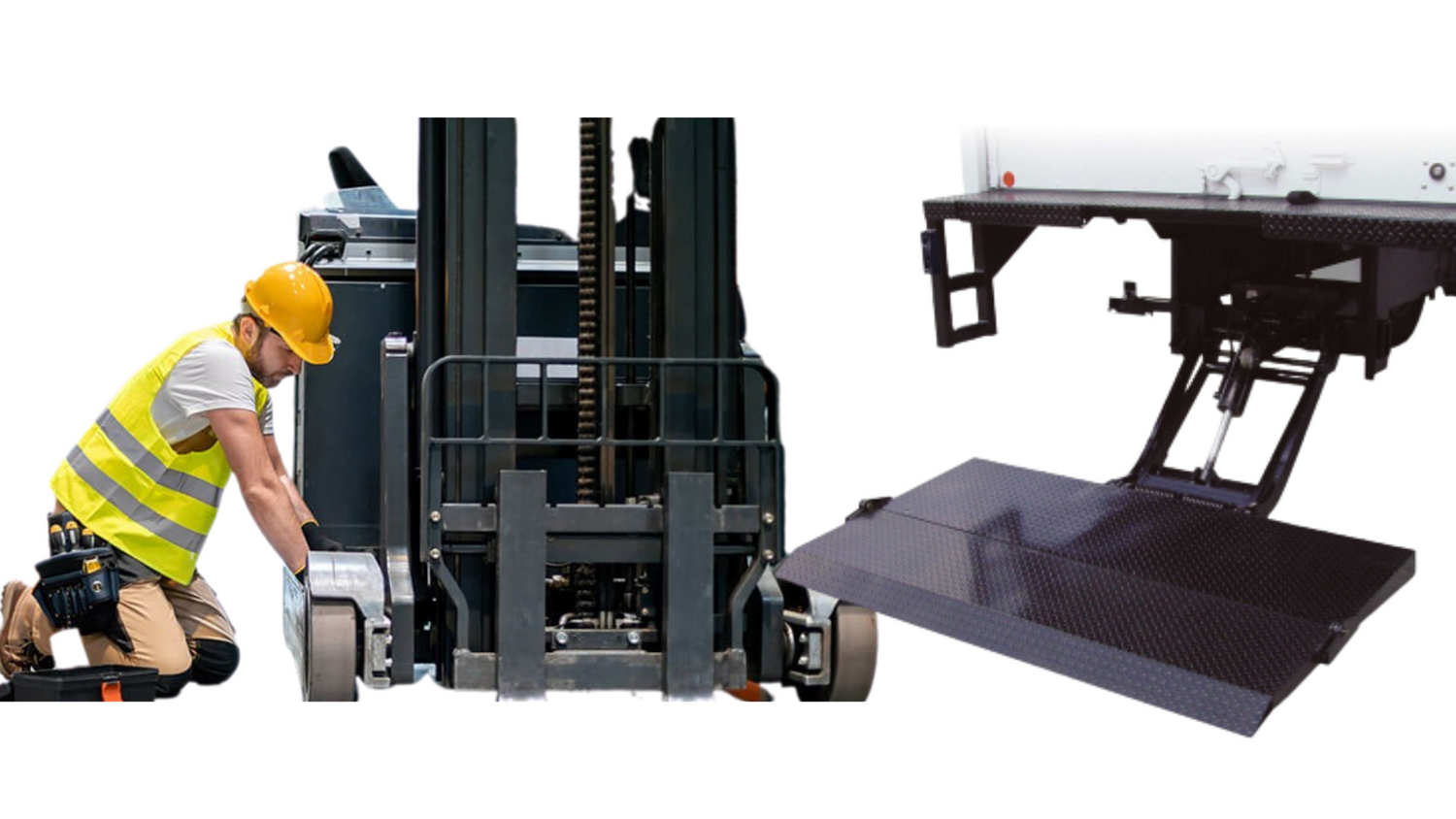

Forklift Maintenance and Hydraulic Repair: A Complete Guide from Liftgates to Lift Cylinders

Forklifts and hydraulic systems are the backbone of many industries, from warehouses and logistics to construction and manufacturing. When these critical pieces of equipment break down, the consequences can be severe—costly downtime, delayed operations, and even safety hazards. That’s why regular maintenance and timely repairs are essential for keeping your business running smoothly.

In this guide, we’ll explore everything you need to know about forklift maintenance and hydraulic repair, from common issues to preventative tips. Whether you’re in Orlando, FL, Raleigh, NC, or the surrounding areas, this guide will help you understand the importance of keeping your equipment in top condition—and how AAA Forklifts can help.

What’s Inside This Guide

- Why Downtime Costs More Than You Think

- Common Forklift Problems and How to Fix Them

- How Hydraulic Systems Work (and Why They Fail)

- Pro Tips for Keeping Your Forklift in Top Shape

- When It’s Time to Call the Pros

- Serving Orlando and Beyond

- Helping Raleigh Businesses Stay Productive

- Why Choose AAA Forklifts for Your Repair Needs

- Final Thoughts: Keep Your Business Running Smoothly

Why Downtime Costs More Than You Think

Downtime is one of the biggest headaches for businesses that rely on forklifts and hydraulic systems. When equipment breaks down, the costs can add up fast—not just in repairs, but in lost productivity and missed deadlines. Here’s a look at the numbers:

"According to a study by Aberdeen Group, unplanned downtime costs businesses an average of $260,000 per hour. For companies relying on forklifts and liftgates, even a few hours of downtime can lead to significant losses."

"A report by Material Handling & Logistics found that 45% of forklift failures are due to inadequate maintenance, leading to costly repairs and operational delays."

These numbers show just how important it is to stay on top of maintenance and repairs. By catching small issues early, you can save your business time, money, and a lot of stress.

At AAA Forklifts, we get it. That’s why we created our Never Down Program, offering 24/7 emergency services, same-day repairs, and 50% off rental lifts to keep your operations running smoothly. With our expertise and commitment to customer satisfaction, you can trust us to minimize disruptions and keep your business moving forward.

Common Forklift Problems and How to Fix Them

Forklifts are tough machines, but they’re not invincible. Over time, wear and tear can lead to a variety of issues. Here are some of the most common problems—and how to address them:

Hydraulic System Failures

Hydraulic systems are the workhorses of forklifts, but they’re also one of the most common sources of trouble. Issues like leaks, pressure problems, cylinder damage, and drifting can bring your operations to a standstill.

-

Signs of Trouble:

- Drifting: If your forklift’s mast or load slowly lowers or drifts when it shouldn’t, this is a clear sign of hydraulic system issues. Drifting often indicates internal leaks in the hydraulic cylinders or valves.

- Fluid Leaks: Puddles of hydraulic fluid under your forklift or visible leaks around hoses, seals, or cylinders are a red flag. Leaks can lead to a loss of pressure and reduced performance.

- Slow or Uneven Lifting: If your forklift struggles to lift loads or moves unevenly, it could be due to low hydraulic fluid levels, air in the system, or worn-out components.

- Unusual Noises: Whining, knocking, or grinding noises from the hydraulic pump or cylinders often indicate problems like cavitation (air bubbles in the fluid) or worn-out parts.

- Overheating: If the hydraulic system gets too hot, it could be due to a clogged filter, low fluid levels, or excessive strain on the system.

-

What to Do:

- Inspect hoses, seals, and cylinders regularly for wear and tear.

- Check hydraulic fluid levels and top off as needed.

- Address leaks or pressure issues immediately to prevent further damage.

- If you notice drifting or slow operation, call a professional to diagnose and repair the issue before it leads to a complete failure.

Engine and Transmission Problems

The engine and transmission are the heart of your forklift. When they’re not working right, neither is your business.

- Signs of Trouble: Trouble starting, loss of power, weird noises.

- What to Do: Keep up with oil changes, check fluid levels, and schedule regular inspections.

Brake and Steering Issues

Forklifts need precise braking and steering to operate safely. Problems here can lead to accidents and injuries.

- Signs of Trouble: Brakes feel off, steering is unresponsive, squeaking or grinding noises.

- What to Do: Inspect brakes and steering components regularly, and replace worn parts as needed.

Electrical System Malfunctions

Modern forklifts rely on electrical systems for everything from ignition to lighting. When these systems fail, it can cause a lot of headaches.

- Signs of Trouble: Dead batteries, flickering lights, controls not working.

- What to Do: Check battery connections, replace faulty wiring, and make sure everything is charged up.

How Hydraulic Systems Work (and Why They Fail)

Hydraulic systems are what make forklifts and liftgates so powerful. They use pressurized fluid to lift and move heavy loads. But like any system, they’re prone to issues like leaks, pressure loss, and cylinder damage.

At AAA Forklifts, we specialize in hydraulic system repairs, including cylinder repairs, hose replacements, and leak detection. Our team knows how to diagnose and fix hydraulic problems quickly, so you can get back to work with minimal downtime.

"Hydraulic systems are the lifeline of forklifts and liftgates. Regular maintenance and timely repairs are essential for preventing costly breakdowns and ensuring safe operation."

Pro Tips for Keeping Your Forklift in Top Shape

Preventative maintenance is the best way to keep your forklifts running smoothly and avoid costly repairs. Here are some tips to help you stay ahead of the game:

- Inspect Regularly: Check your forklift daily or weekly for signs of wear and tear. Look for leaks, cracks, or unusual noises.

- Check Fluids: Keep an eye on hydraulic fluid, engine oil, and coolant levels. Low fluids can lead to overheating and system failures.

- Clean and Lubricate: Keep moving parts clean and well-lubricated to reduce wear. Dirt and debris can cause damage over time.

- Fix Small Issues Fast: Don’t ignore minor problems—they can turn into big ones quickly. Address issues like leaks or strange noises immediately.

- Schedule Professional Maintenance: Partner with a trusted provider like AAA Forklifts for regular checkups. Our experts will ensure your equipment is in top condition.

Need a maintenance plan? Explore our maintenance programs today!

When It’s Time to Call the Pros

While regular maintenance can prevent many issues, there are times when you need to call in the experts. Here are some scenarios where professional repair services are a must:

- Complex Hydraulic Issues: Leaks, pressure problems, and cylinder damage require specialized knowledge and tools.

- Major Engine or Transmission Problems: These issues can be dangerous to tackle without professional training.

- Safety Concerns: If your forklift poses a safety risk, it’s essential to get it repaired right away.

- Emergency Repairs: When downtime isn’t an option, AAA Forklifts’ 24/7 emergency services are here to help.

With our Never Down Program, AAA Forklifts ensures that your business never faces extended downtime. Whether it’s a hydraulic leak or an engine failure, our team is available 24/7 to provide fast, reliable repairs. Plus, if your forklift needs to stay in the shop, we offer 50% off rental lifts to keep your operations moving.

Serving Orlando and Beyond

Orlando’s booming logistics and warehouse industries rely heavily on forklifts to keep operations running smoothly. But the region’s high humidity and demanding workloads can take a toll on equipment.

At AAA Forklifts, we understand the unique challenges faced by Orlando businesses. That’s why we offer expert forklift repair and maintenance services tailored to the local environment. In addition to Orlando, we serve businesses in Tampa, Daytona Beach, and Melbourne, ensuring that companies across Central Florida have access to reliable forklift repair services.

Helping Raleigh Businesses Stay Productive

Raleigh’s growing manufacturing and tech sectors depend on forklifts for efficient operations. But seasonal weather conditions and heavy workloads can lead to equipment wear and tear.

AAA Forklifts is proud to serve Raleigh and the surrounding areas, including Durham, Chapel Hill, and Greensboro. Our team has the expertise to keep your forklifts and hydraulic systems running smoothly, no matter the challenges.

Why Choose AAA Forklifts for Your Repair Needs

When it comes to forklift repair and maintenance, partnering with a professional service provider like AAA Forklifts offers a lot of benefits:

- Expertise: Our team has the knowledge and experience to diagnose and repair complex issues.

- High-Quality Parts: We use only the best parts and tools for repairs and replacements.

- Fast Turnaround: With same-day repairs and 24/7 emergency services, we minimize downtime and keep your business running.

- Safety and Compliance: We make sure your equipment meets all safety and regulatory standards.

With over 106 5-star Google reviews, AAA Forklifts has built a reputation for excellence in forklift repair and hydraulic services. Our customers trust us to deliver fast, reliable, and professional service every time.

Final Thoughts: Keep Your Business Running Smoothly

Forklifts and hydraulic systems are essential for many industries, but they need regular maintenance and timely repairs to stay in top condition. By addressing small issues early and partnering with a trusted provider like AAA Forklifts, you can avoid costly downtime and keep your operations running smoothly.

For professional forklift repair and hydraulic services in Orlando, Raleigh, and beyond, trust AAA Forklifts. Visit our website or call us today to learn more about our 24-hour emergency services, same-day repairs, and 50% off rental lifts. Let us help you keep your business lifted—from liftgates to lift cylinders.

FAQs

Q: How often should I service my forklift?

A: We recommend servicing your forklift every 200-250 hours of operation or at least once every three months.

Q: What are the signs of hydraulic system failure?

A: Common signs include slow or uneven lifting, fluid leaks, and unusual noises.

Q: Do you offer emergency forklift repair services?

A: Yes, AAA Forklifts offers 24/7 emergency repair services to minimize downtime.

Q: How can I prevent forklift breakdowns?

A: Regular inspections, fluid checks, and timely repairs are key. Partner with AAA Forklifts for a customized maintenance plan to stay ahead of potential issues.

What to Do Next

"If your forklift or hydraulic system is giving you trouble, don’t wait—get it fixed fast. AAA Forklifts offers 24/7 emergency services, same-day repairs, and 50% off rental lifts to keep your business running smoothly.

In Florida, call us at (407) 695-4387 or email us at info@aaaforklifts.com.

In North Carolina, call us at (919) 925-2217 or email us at info@aaaforklifts.com.

You can also visit aaaforklifts.com to explore our selection of completely refurbished forklifts for any job. Plus, we come to your work site—so you don’t have to worry about transporting your equipment. Let us help you keep your business lifted—from liftgates to lift cylinders."

Follow Us on Social Media

© 2025 AAA Forklifts Blog. All Rights Reserved.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.