As we enter 2025, it’s the perfect time to revisit the topics and trends we covered in 2024. From exploring the latest forklift technologies to providing practical advice for fleet management, we’ve published articles designed to help businesses thrive in the ever-evolving material handling landscape.

Here’s a recap of our key articles from 2024 and a glimpse into what’s on the horizon for 2025.

2024 Highlights: Key Topics We Covered

1. Future-Proofing Forklift Fleets

In our article "Future-Proofing Forklift Fleets for 2025", we explored strategies businesses adopted to stay resilient in the face of rapid industry changes. These included transitioning to electric forklifts for their cost and sustainability benefits, implementing smarter fleet management tools to improve uptime, and providing operators with targeted training to maximize productivity.

“Future-proofing isn’t just a buzzword—it’s about staying agile and prepared in a fast-evolving industry.”

2. Forklift Trends That Defined 2024

Our piece on "2025 Forklift Trends" identified key themes like sustainability, customization, and technology integration. We highlighted the growing use of IoT for real-time fleet monitoring and the rise of automation in warehouses, even for medium-sized businesses. This shift marks the beginning of an era where data and efficiency drive every decision.

“The transition to smarter, more sustainable operations gained significant traction this year.”

3. Electric vs. Gas-Powered Forklifts

In "Electric vs. Gas-Powered Forklifts", we analyzed the pros and cons of both models. While electric forklifts gained widespread adoption due to their environmental benefits and low operating costs, gas-powered forklifts maintained relevance for outdoor and heavy-duty applications. Businesses began to embrace the long-term cost savings of electric fleets, especially with advancements in battery technology.

“Electric forklifts are no longer just an option—they’re quickly becoming the standard for many operations.”

4. Cutting-Edge Technologies in Material Handling

In our exploration of "Top Trends in Forklift Technology", we covered the transformative impact of telematics, robotics, and augmented reality. Telematics allowed businesses to track performance data and optimize operations, while robotics enhanced automation for repetitive tasks. AR also began playing a role in training, enabling operators to familiarize themselves with equipment virtually before hands-on use.

“Technological innovation is making forklifts smarter, safer, and more productive than ever.”

5. Sustainability in Forklift Operations

In "Lithium-Ion Onboard Charging Solutions", we highlighted innovations in charging technology. Onboard charging systems for lithium-ion batteries became a game-changer, enabling operators to charge during downtime and reducing the need for centralized charging stations. These advancements align with the push for more sustainable and efficient operations.

“Charging innovations are reducing downtime while supporting sustainability goals.”

What’s Ahead for 2025: Forklift News and Trends

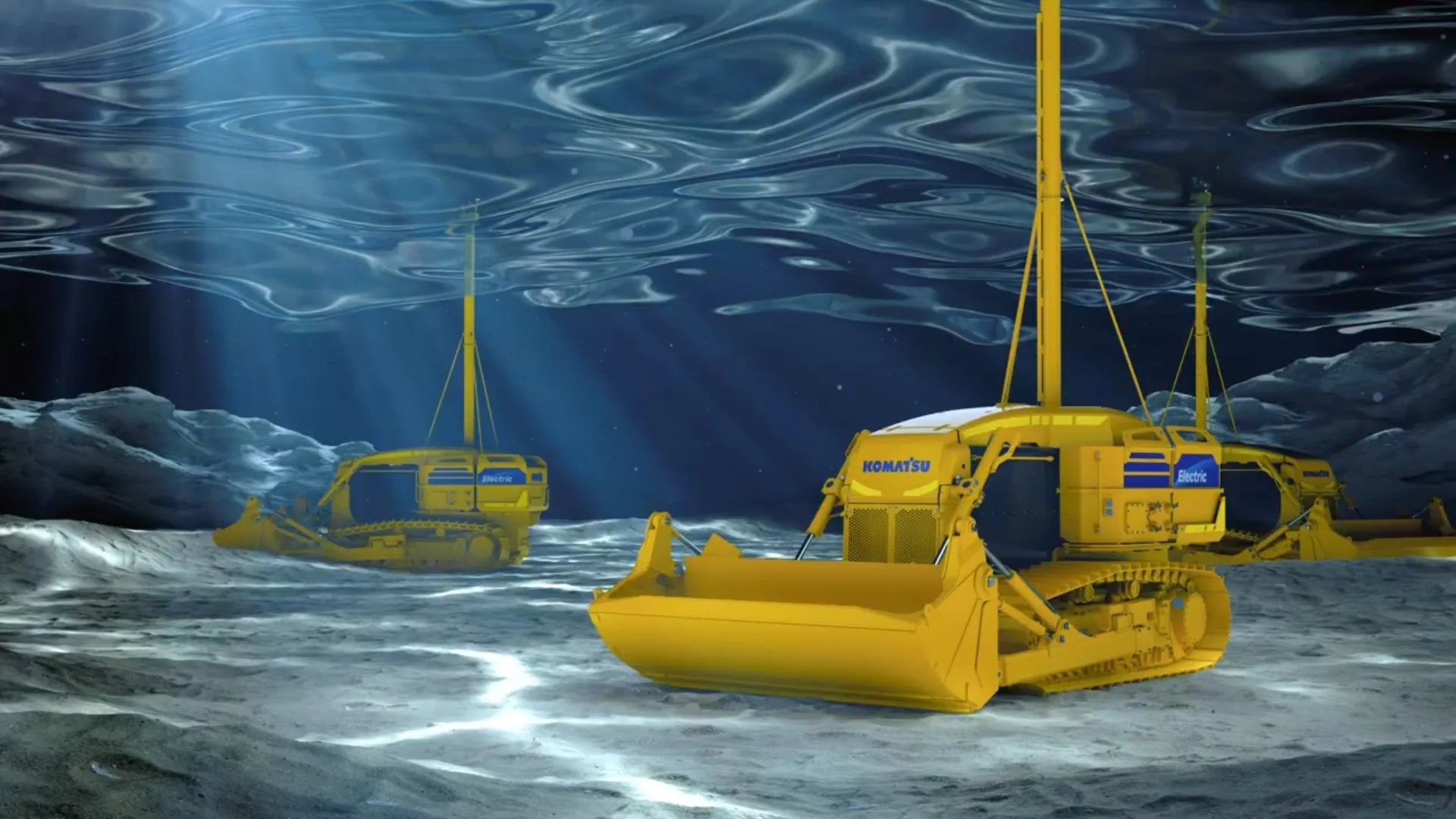

1. New Developments in Hydrogen-Powered Forklifts

Major forklift manufacturers are ramping up efforts to create hydrogen-powered forklifts as part of a broader shift toward zero-emission solutions. Companies like Toyota and Hyster-Yale are investing in hydrogen fuel cell technology to address the limitations of battery-electric models, such as long charging times and limited range for heavy-duty applications.

2. Advances in Autonomous Forklifts

The automation trend continues to accelerate in 2025, with autonomous forklifts becoming more accessible to mid-sized businesses. Improvements in navigation systems, AI-driven decision-making, and fleet integration tools are enabling more seamless warehouse operations. Notably, innovations in lidar technology are reducing the costs and improving the accuracy of autonomous forklifts.

3. The Rise of Modular Forklift Designs

Customization remains a key focus in the forklift industry, and 2025 will see the rise of modular forklift designs. These forklifts feature interchangeable components, such as attachments for specific tasks or terrain-specific tires, allowing businesses to tailor their fleets to diverse operational needs without investing in multiple specialized machines.

4. New Safety Standards and Regulations

Safety remains a top priority, and new regulations from organizations like OSHA and ANSI are expected to influence forklift design and workplace practices. Manufacturers are introducing enhanced safety features such as automated speed controls in high-risk areas, pedestrian detection systems, and advanced warning systems for collision avoidance.

5. Faster, Smarter Charging for Electric Forklifts

Lithium-ion technology is evolving, with manufacturers introducing faster, more efficient charging solutions. Onboard charging systems are becoming standard for many electric forklifts, enabling operators to charge equipment during breaks without returning to a central charging station.

These advancements are set to make 2025 a pivotal year in forklift innovation, offering businesses the opportunity to improve efficiency, sustainability, and safety.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.